PILLOW MAKING MACHINES: HOW TO ELEVATE PRODUCTION

From raw material processing to filling, from sewing to packing

In the realm of pillow production, efficiency and quality are paramount. Pillow making machines play a crucial role in streamlining this process, ensuring pillows are fluffy, well-packed, and ready for distribution.

From processing fibers, feathers, foam to filling or stuffing, all the way to sewing and packaging, having the right equipment will help you optimize every step of your pillow production line. But what exactly are these machines, and how do they contribute to the pillow manufacturing industry?

Investing in pillow machines yields several advantages for pillow manufacturers.

Cost

Savings

By automating pillow making processes, businesses can lower labor costs and minimize material wastage, leading to substantial savings in the long run.

Increased

Productivity

Pillow filling machines significantly speed up the production process, allowing manufacturers to meet demand more effectively and reduce lead times.

Customization

Options

Advanced pillow making machines offer customization features, enabling manufacturers to create pillows tailored to specific customer preferences, such as size, firmness, and material.

PROCESSING STEPS

The pillow production process consists of several distinct stages, each requiring precise control and coordination. At the heart of the line is the crucial process of stuffing or filling, in which the material (fiber, microfiber, feathers and down, foam shavings and various customized blends) is placed inside the cover, ensuring optimal fluffiness and consistency.

RAW MATERIAL PROCESSING AND WASTE RECYCLING

COVER MAKING MACHINE

PILLOW FILLING AND PILLOW STUFFING MACHINES

PILLOW SEWING MACHINES

PILLOW PACK MACHINES

PILLOW TYPE

The types of cushions are multiple and differ according to the type of use and the infinite variations in materials, shapes and textures: pillows for sleeping, pillows to decorate the house, seats and backs for sofas and chairs, orthopedic pillows, pillows for physical activity, cushions for travel etc.

BLOWN PILLOWS

Blown pillows offer endless possibilities in filling materials – from fiber and feathers to shredded foam, recycled fabrics or blends. Our equipment ensures seamless filling processes, allowing for flexibility and precision in product creation.

DISCOVER OUR LINES FOR BLOWN FIBER PILLOWS

WANT TO LEARN MORE ABOUT FILLING MATERIAL? LINK BLOG

CARDED FIBER PILLOWS

Carded fiber pillows are known for their firmness and support. After carding, the batt has to be cut to size, rolled and inserted into the pillowcase. The challenge? Making sure the stuffing is precise and the pillow case is filled uniformly.

DISCOVER OUR LINES FOR CARDED FIBER PILLOWS

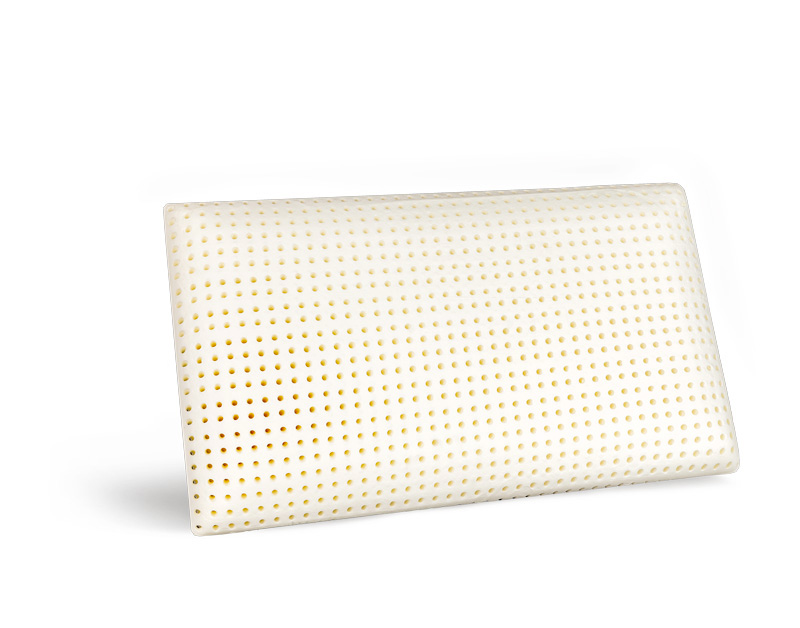

FOAM AND LATEX PILLOWS

Renowned for their excellent support and pressure relief, foam and latex pillows need to be carefully stuffed inside the pillowcase before proceeding to packaging.

DISCOVER OUR LINES FOR FOAM AND LATEX PILLOWS

Do you want to make your own foam pillows? Have a look at our single block foam making machine and discover the advantages of in-house foam production. Learn more

DECORATIVE CUSHIONS

Characterized by inner and outer cases and fiber filling, decorative cushions blend functionality and style.

Often packaged in multipacks or twin packs, these cushions require meticulous stacking procedures prior to rolling or flat packing, ensuring efficient production and impeccable presentation.

DISCOVER OUR LINES FOR DECORATIVE CUSHIONS

SOFA CUSHION

Sofa cushions are often multi-chamber for enhanced support, which can result in a much slower process. With that in mind, our equipment has been designed to support and guide operators in the filling and, in particular, in the chamber filling sequence.

DISCOVER OUR LINES FOR DECORATIVE CUSHIONS

Fill out the form to receive a customized consultation, and together we will find the right solution for your needs.

FAQ

In general, the pillow production process includes:

- The preparation of the raw material (synthetic and natural fibers of various kinds, feather, polyurethane rubber block, polyurethane flake, chipboard, mixtures, recycled fibers from noble textile waste, etc.)

- The filling inside a cover, handled by weighing systems with weight accuracy appropriate to the characteristic of each raw material

- The lining stitching, whose point can be selected between different types (overlock, lockstitch and ultrasound)

- The packaging (rolled or flat, single or multiple, plastic or paper, in boxes or bags, in recycled material). In addition to having a protective purpose of the product and reducing the space in warehouses and in means of transport, packaging is a distinctive factor of each brand.

A fiber opening machine is used in pillow making to open virgin or recycled fiber as efficiently as possible; the more polyester fiber is opened with an adequate machinery, the more the yield in terms of volume and resilience. The correct handling of the opened fiber during mixing with other materials allows to keep intact the opening volume throughout the whole process until packaging and use.

Carded fiber, opened fiber, microfiber, foam, shredded foam, feathers, down: these are the most commonly used pillow filling materials. Mixtures of these materials are also very frequent, allowing combining the characteristics of the various materials in order to give the highest quality to the final product.