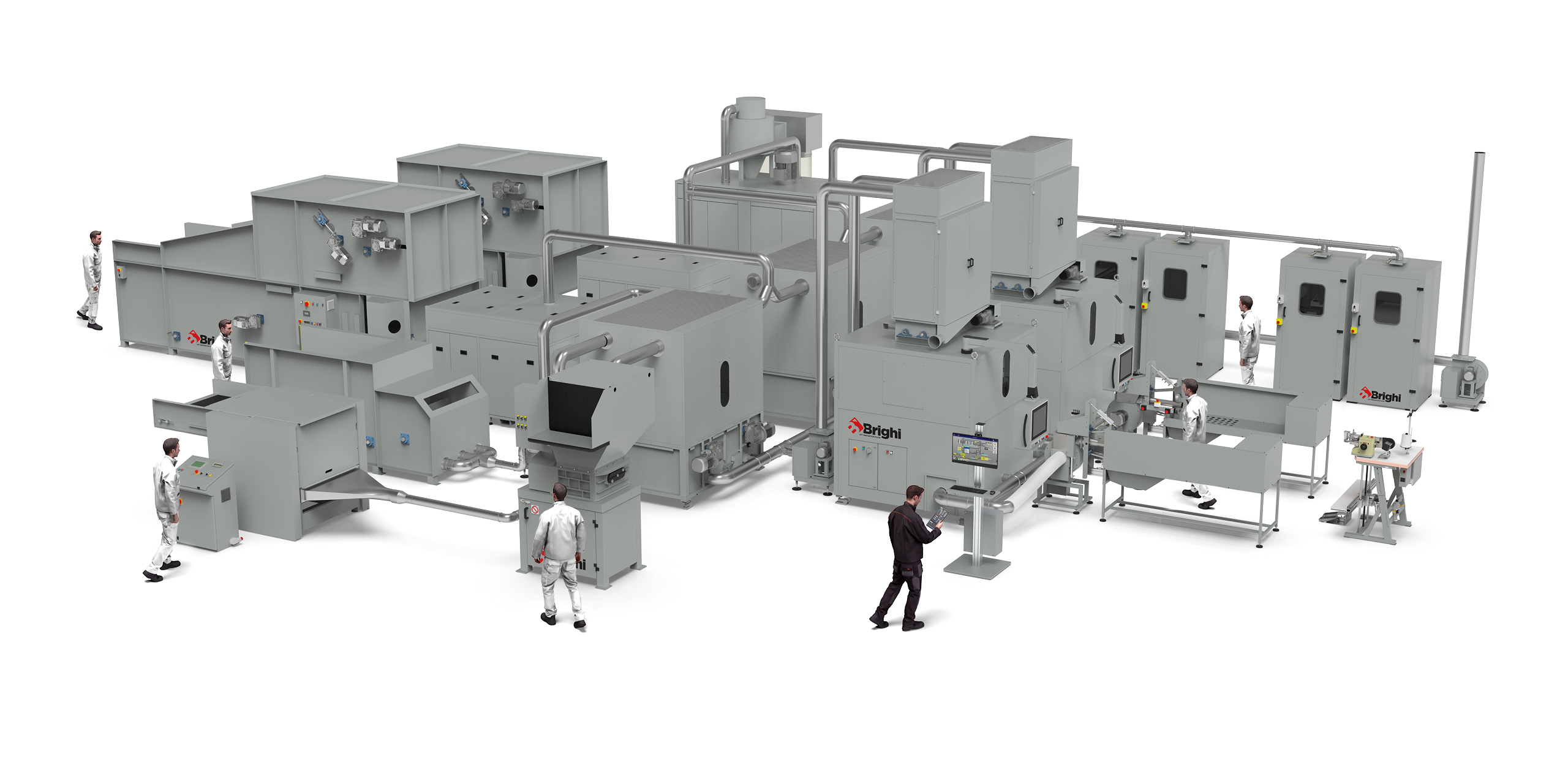

RAW MATERIAL PROCESSING AND WASTE RECYCLING LINE

- RAW MATERIAL PROCESSING

- WASTE RECYCLING

- RAW MATERIAL PROCESSING

- WASTE RECYCLING

- RAW MATERIAL PROCESSING

- RAW MATERIAL PROCESSING

- IoT control and management

- RAW MATERIAL PROCESSING

- RAW MATERIAL PROCESSING

- SEWING

This line is designed to process many different types of filling materials (such as fiber, microfiber, down, feather, polyurethane) and for the recovery of fabric, fiber and foam scraps from other processes.

The machines used to process raw materials are:

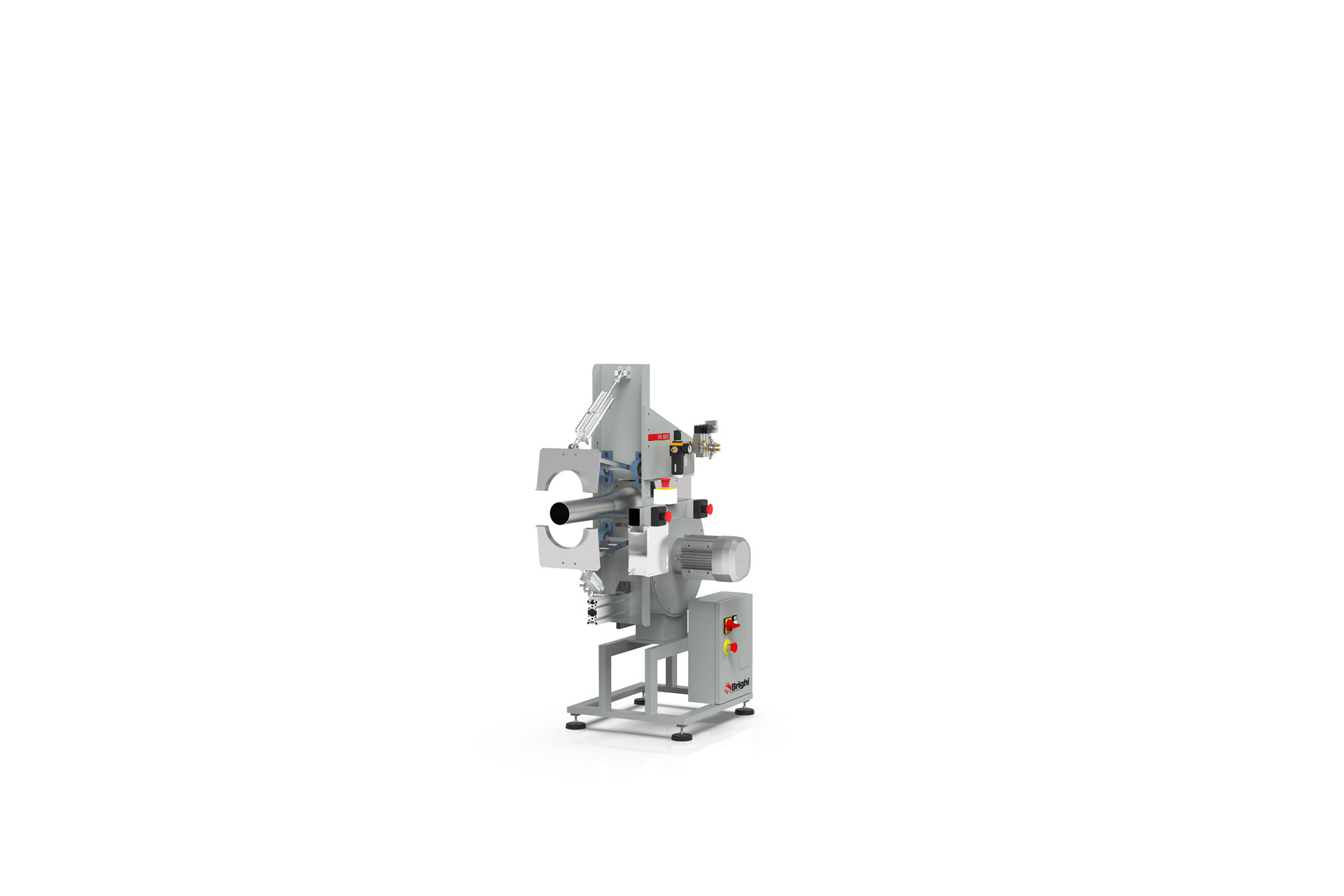

- Loose feather and shredded foam loader mod. HL-400;

- Fiber bale loader mod. HL-500;

- High-capacity fiber bale loader mod. HL-1500;

- Fiber opener mod. OF-550;

- Ball fiber machine mod. BF-300;

- Mixer mod. MX-500 for blends.

It is possible to use these materials for the production of finished products by filling pillows, cushions or other soft items with our blending machine and our pre-weighing and blown filling systems mod. MAC. In addition, the shredding machine mod. SF-200 for recovering foam scraps and the fabric and fiber waste opener mod. SF-300 can also be incorporated into the line.

Once processed, these materials can also be marketed as loose product, intended for producers of various kinds of upholstered items and sold in large vacuum bags thanks to our cabin system mod. BV-100.

- Main Features

Controlled treatment of the raw material: maximum opening of the fiber, significant increase in volume, controlled blends

Recycling of waste materials and transformation into noble raw materials suitable for new products, avoiding waste and disposal costs

Accurate pre-weighing system and processing capacity of all raw materials and creation of mixtures with different components

Specific system for filling bags in depressurized cabins or for padding

Maximum quality standard of the finished product: homogeneity of filling and controlled mixing

Performance guaranteed thanks to the electronic management of the machinery that manages all the parameters for production change without mechanical interventions on the plant

Clean working environment and maximum hygiene in the treatment of raw materials

Quick payback: reduction in costs of disposal and transformation of waste into raw material to be reused for new products

Compact and modular line: each module of the line represents a process designed to reduce the use of space and adaptable to any customer environment.

Flexibility and long-lasting investment guarantee with step-by-step implementation of your system as your business requires it

Production data management and monitoring to support strategic and organizational decisions thanks to our Automation Intelligence software