POLYURETHANE PRODUCTION LINE FOR MATTRESSES AND PILLOWS

This line is made up of a low-pressure machine, FP-400, designed for the production of soft or rigid polyurethane blocks in discontinuous of various shapes, densities and colors. This line can be customized to the customer’s needs and can handle poly-oils, a wide variety of liquids and additive powders of various colors and fragrances, offering maximum flexibility and, above all, unique products to manufacturers of sofas, mattresses, soft components for cars or other types of shaped products.

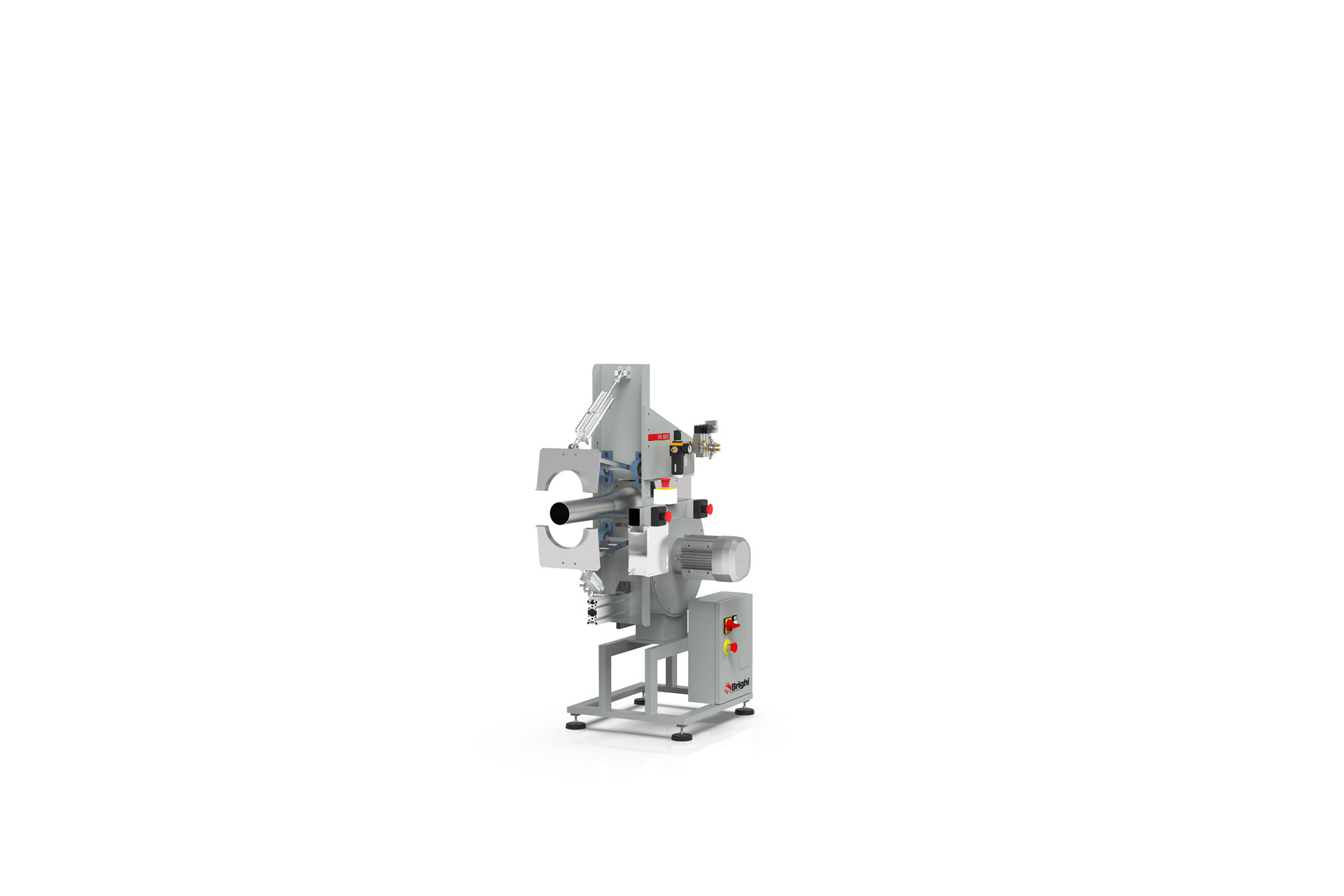

The scraps produced during the working phases can be recycled thanks to our shredding machines mod. SF-200, depending on the recycled material. By recycling the scrap and waste of polyurethane, our customers can obtain a secondary raw material for the production of new high-quality products, reducing costs and contributing to environmental preservation.

Here’s an example of a recycling line:

- Main Features

Significant reduction in raw material and transport costs.

Maximum customization of the product in weight, shape and type (with mixing of gel particles, dyes and perfuming additives)

Quick payback: reduction in raw material, transport and storage costs

Drastic reduction in warehouse stock and production on sales

Maximum quality standard of the finished product: homogeneity of the physical characteristics of the polyurethane

Recycling of waste materials and transformation into noble raw materials suitable for new products, avoiding waste and disposal costs

Self-cleaning systems that avoid the use of liquid solvents

Performance guaranteed thanks to the electronic management of the machinery that manages all the parameters for production change without mechanical interventions on the plant

Compact and modular line: each module of the line represents a process designed to reduce the use of space and adaptable to any customer environment.

Flexibility and long-lasting investment guarantee with step-by-step implementation of your system as your business requires it

Production data management and monitoring to support strategic and organizational decisions thanks to our Automation Intelligence software

Compact and modular line: each module of the line represents a process designed to reduce the use of space and adaptable to any customer environment.