UPHOLSTERY

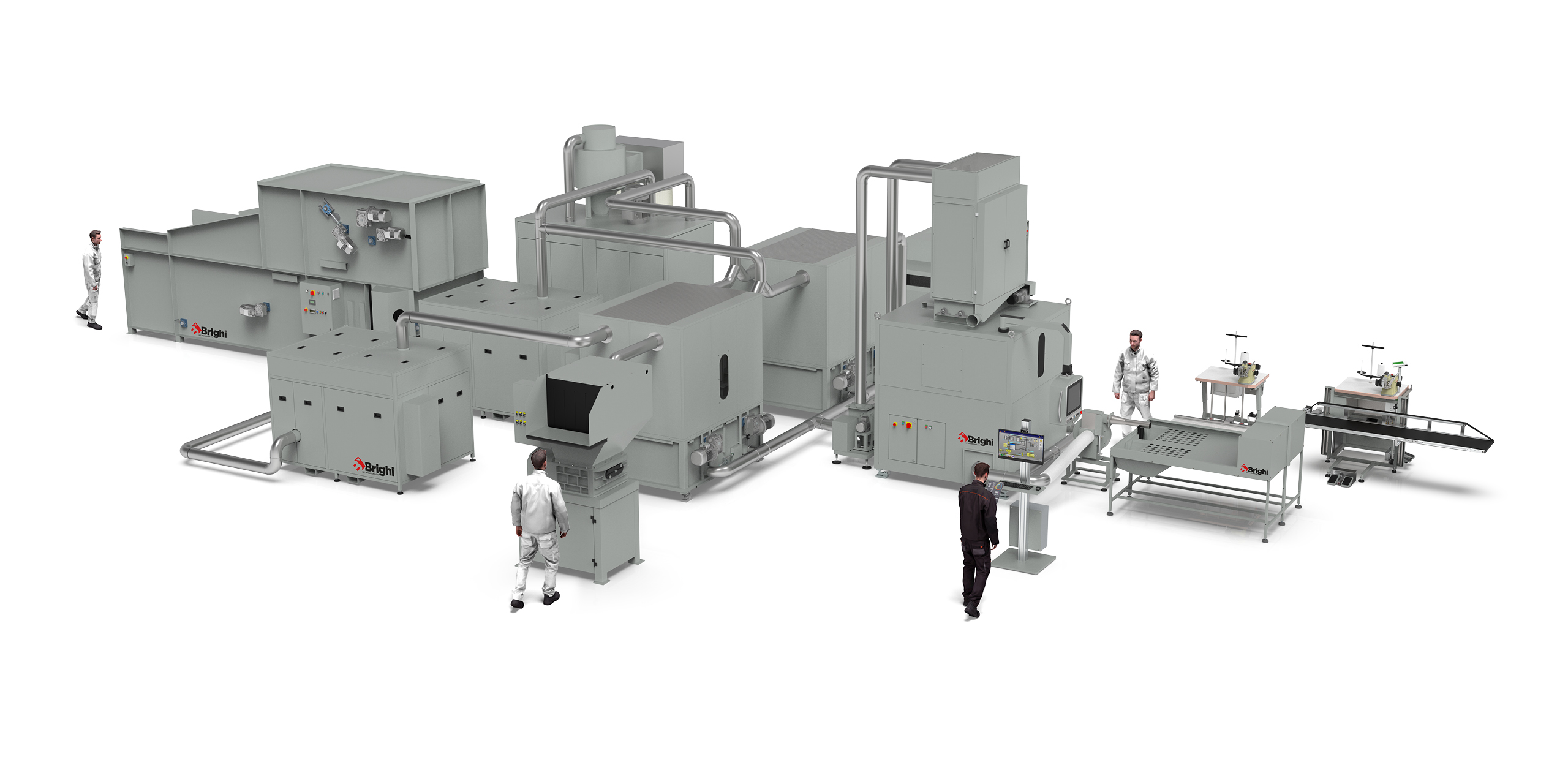

The line is designed for filling and closing components of sofas, armchairs and upholstery of various kinds.

The configuration includes different solutions that allow filling both with different materials (fiber / fiber balls / feathers/ down…) and recycled materials (polyurethane, fabrics) as well as blends in different proportions of all the components mentioned, thanks to several mixing stations. This line allows the greatest universality in the use of raw materials as a single pre-weighing system can manage all the raw materials required.

Here’s the configuration we presented:

- Fiber bale loader mod. HL-500 or HL-1500 (depending on the production volumes required) for bales of virgin fiber

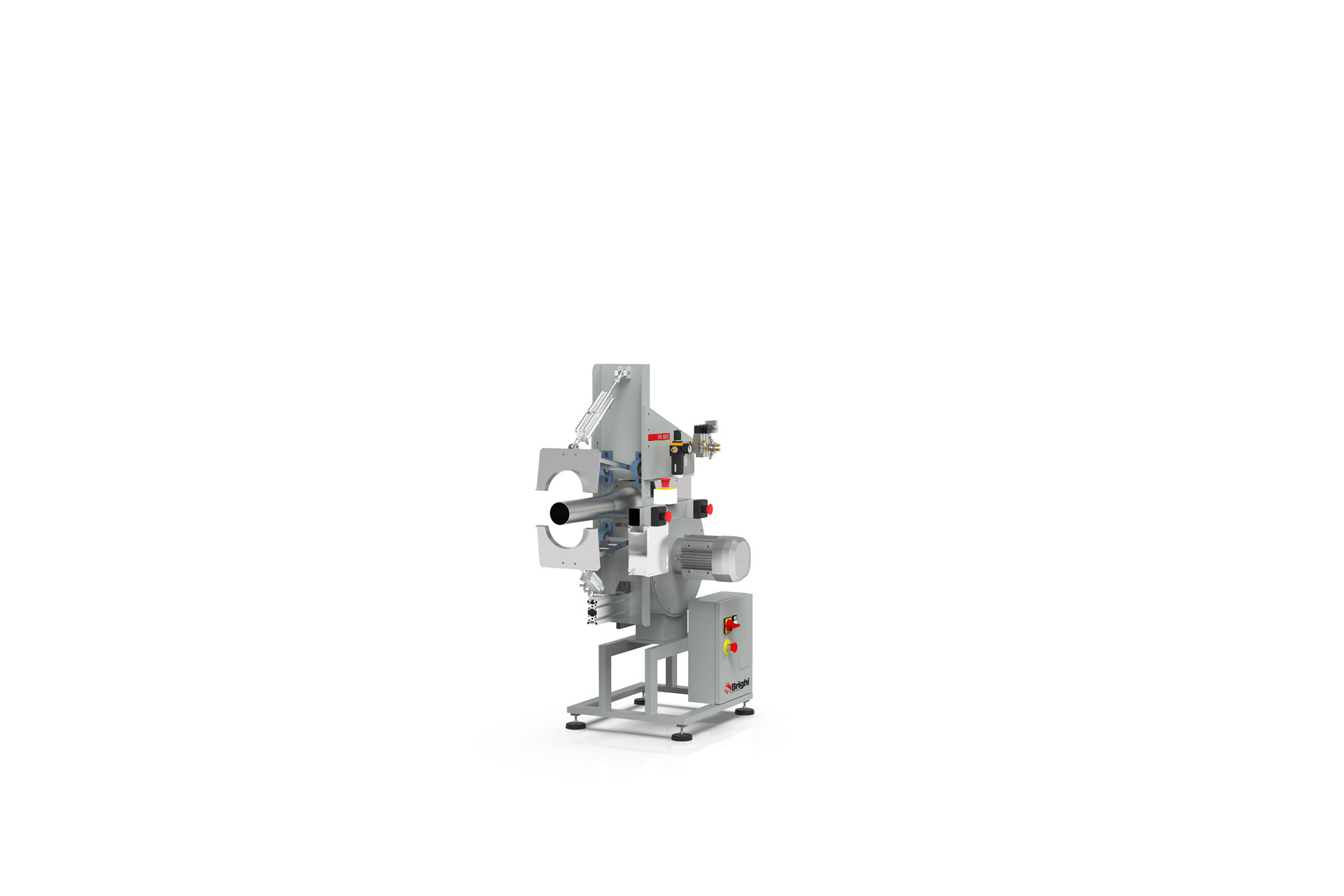

- Shredding machine mod. SF-200 for polyurethane scraps.

- Two fiber openers mod. OF-550,

- Ball fiber machine mod. BF-300;

- Mixing station mod. MX-500 to mix fiber balls and feathers or down; you can also blend in the recycled materials;

- Pre-weighing and filling system mod. MAC-300D, designed ad hoc for the management of various materials and the filling of products, including multi-chamber, facilitating the operator both from the point of view of weighing accuracy and performance.

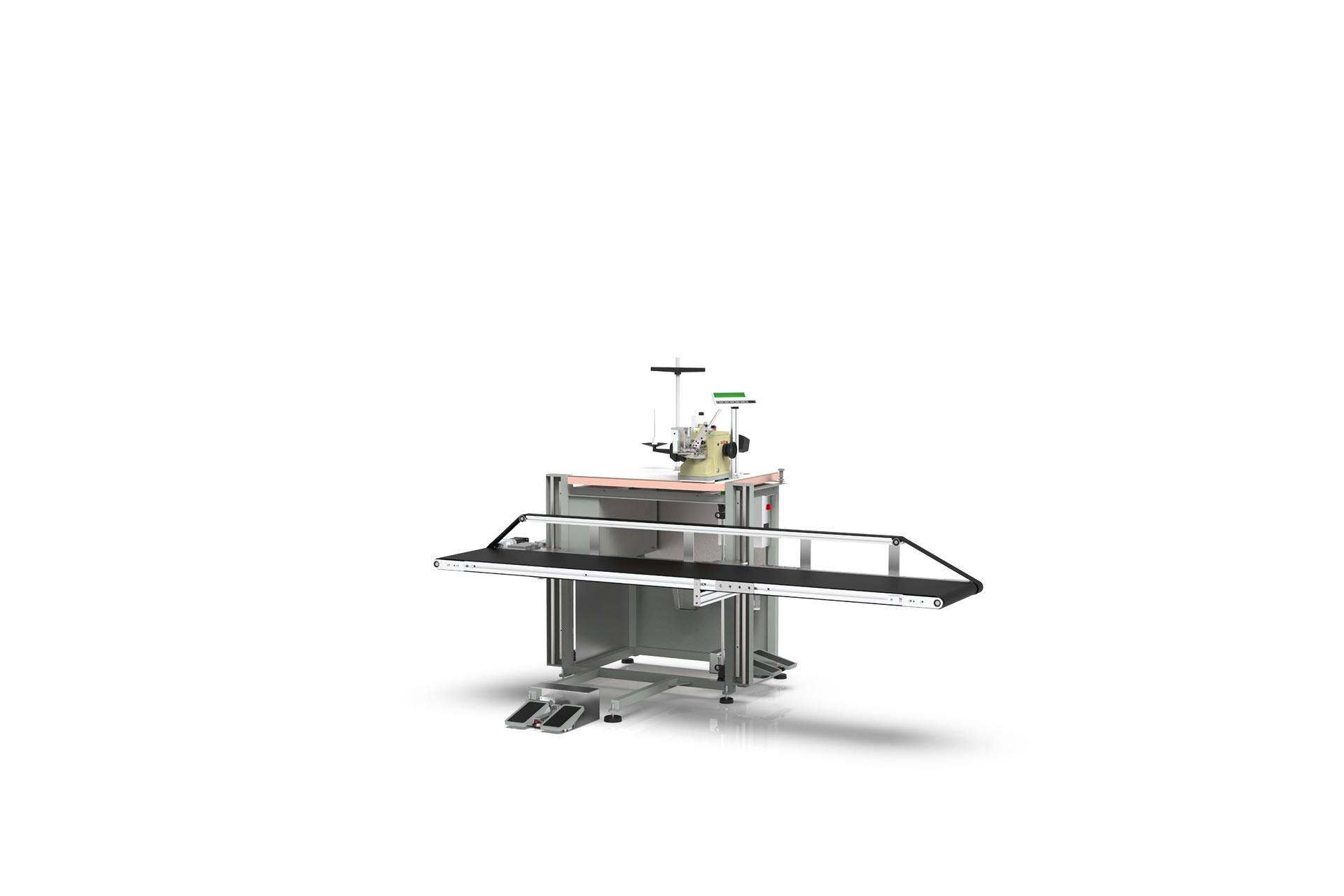

- Sewing systems mod. G164C and mod. G164U, single thread, are specific to close filled products, such as seats, backs, padded items of various shapes, sizes and weights, with high sewing speeds up to 1900 Rpm. The special stitching point has been specially designed for a flat seam that gives quality to the internal components of the sofas and which at the same time has a sealing property against the spilling up of internal materials, especially in the case of shreds, feathers and down. In addition, the G164U version is specific for the assembly with stitching of polyurethane sheets and batts which are the optimal material for the creation of the interiors of quality sofas (typical of the Made in Italy sofa with removable cover known all over the world). The products obtained using this sewing machine do not require the use of glues.

- Main Features

Specific system for multi-chamber cushions being able to fill several chambers at the same time with different weights

Controlled treatment of the raw material: maximum opening of the fiber, significant increase in volume, controlled blends, recycling of waste materials

Accurate pre-weighing system and processing capacity of all raw materials and creation of mixtures with different components

Maximum quality standard of the finished product: homogeneous filling, precise stitching and labeling, perfect sealing of the bag, guaranteed vacuum (if required)

Performance guaranteed thanks to the electronic management of the machinery that manages all the parameters for production change without mechanical interventions on the plant

Clean working environment and maximum hygiene in the treatment of raw materials

Quick payback: reduction of labor and storage costs thanks to efficient and automatic flows

Compact and modular line: each module of the line represents a process designed to reduce the use of space and adaptable to any customer environment.

Flexibility and long-lasting investment guarantee with step-by-step implementation of your system as your business requires it

Production data management and monitoring to support strategic and organizational decisions thanks to our Automation Intelligence software